Polyurea coatings are gaining significant popularity in various industries due to their unique properties, including durability and long service life. When we compare the life expectancy of polyurea coatings with other materials, we find some interesting differences that affect their application in different sectors.

Science Of Polyurea Coatings

To understand why polyurea coatings can outlast other materials, we must first examine their chemistry. Polyurea is formed as a result of the reaction of isocyanate with a component of the resin mixture. The result of this reaction is a very flexible and strong material that is resistant to abrasion, chemicals, and weather conditions. Unlike traditional coatings, which often take several days to fully cure, polyurea coatings can cure within minutes, allowing for faster project completion and reduced downtime.

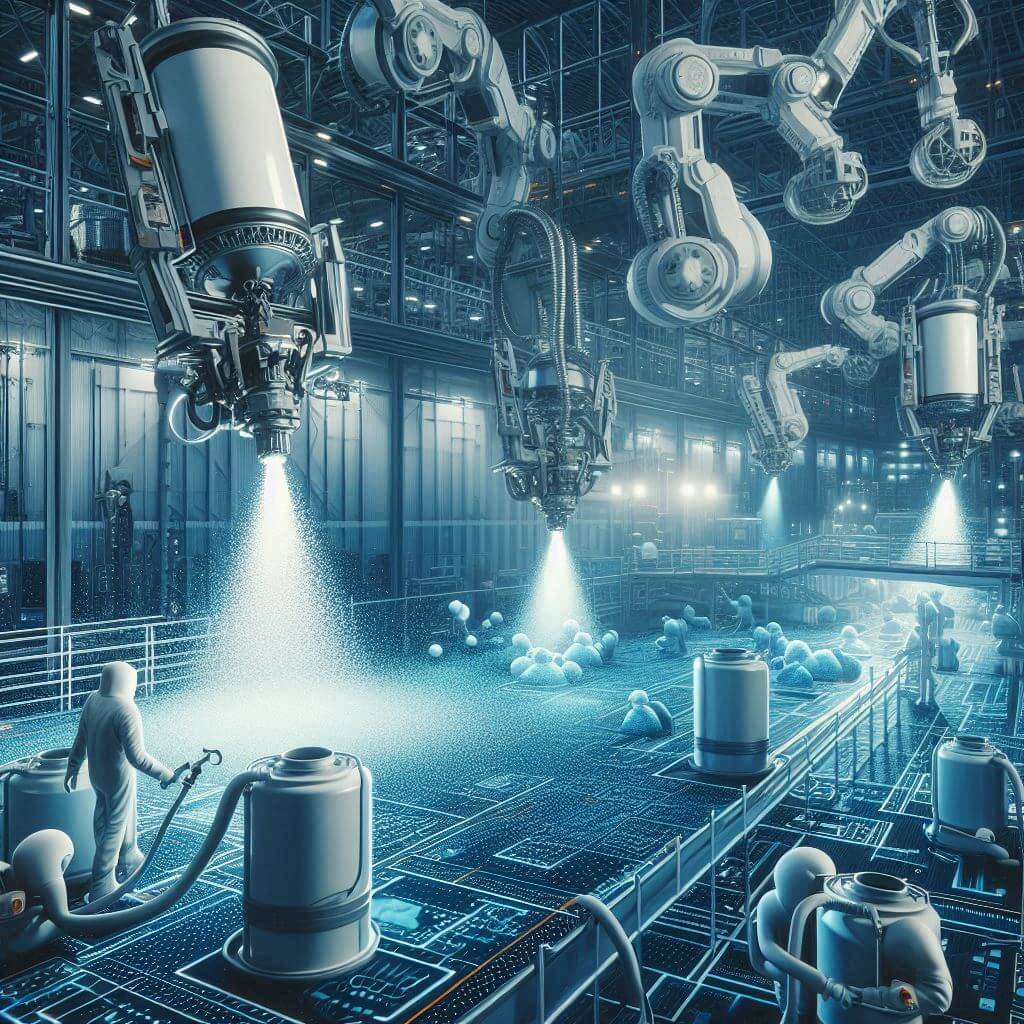

Polyurea coatings are based on a two-component system consisting of an isocyanate and a polyamine. The reaction between these two components occurs extremely quickly, often within seconds, forming a polymer that exhibits exceptional mechanical properties. The rapid reaction and curing process is known as the “hot spray” application, which involves mixing the two components under high pressure and temperature and then spraying the resulting mixture onto the substrate. This process provides a seamless and uniform coating that can accommodate the unevenness of the coated surface.

The elasticity of polyurea is another key factor contributing to its durability. The material can stretch and bend without cracking, which is especially useful in environments subject to temperature fluctuations and mechanical stress. The elongation properties of polyurea can reach 300-400%, that is, the coating can stretch three to four times its original length without breaking. This flexibility helps maintain the integrity of the coating over long periods, thus extending its effective life.

The cross-linked structure of polyurea polymers is another important aspect that contributes to their durability. A dense network of chemical bonds in the polymer matrix provides high tensile strength, tear resistance, and the ability to withstand significant mechanical loads. This cross-linking also provides excellent resistance to a wide range of chemicals, including acids, bases, solvents, and oils, making polyurea coatings suitable for harsh industrial environments.

The cross-linked structure of polyurea polymers is another important aspect that contributes to their durability. A dense network of chemical bonds in the polymer matrix provides high tensile strength, tear resistance, and the ability to withstand significant mechanical loads. This cross-linking also provides excellent resistance to a wide range of chemicals, including acids, bases, solvents, and oils, making polyurea coatings suitable for harsh industrial environments.

Polyurea coatings are also hydrophobic, meaning they repel water. This waterproofing is critical for applications where exposure to moisture is a problem, such as waterproofing foundations, roofs and other structures. The hydrophobic nature of polyurea prevents water penetration and subsequent damage such as corrosion or mold growth, thereby extending the life of the coated structure.

Polyurea coatings demonstrate excellent adhesive properties. They can bond effectively to a variety of substrates including concrete, metal, wood, and plastic. This strong adhesion guarantees a strong adhesion of the coating to the substrate even in difficult conditions, thus providing continuous protection without delamination.

UV resistance is another factor worth noting. Although polyurea itself can be susceptible to UV degradation if exposed for long periods of time, formulations can be modified with UV stabilizers or topcoats can be applied to increase UV resistance. This adaptability allows polyurea coatings to maintain their effectiveness even under direct sunlight, which is important for outdoor applications.

Regarding heat resistance, polyurea can work effectively in a wide range of temperatures. It can withstand extreme cold without becoming brittle, and it can withstand high temperatures without losing its mechanical properties. This makes it suitable for use in various climatic conditions.

Durability In Harsh Conditions

The main advantage of polyurea coatings is their resistance to adverse environmental conditions. For example, in the marine environment, where seawater and ultraviolet (UV) radiation can rapidly degrade traditional coatings, polyurea remains virtually unchanged. This makes it an excellent choice for protecting ship hulls, docks, and other marine structures. The polyurea chemistry provides inherent resistance to salt and wet conditions that promote corrosion and electrochemical reactions that commonly damage metal substrates in marine environments. The coating forms a barrier that prevents harmful agents from entering the protected surfaces, thereby increasing the service life of marine infrastructure.

In industrial environments where equipment and surfaces are frequently exposed to chemicals, heat, and mechanical wear and tear, polyurea coatings provide a reliable protective layer. Industries such as chemical, oil and gas, and manufacturing often operate in environments where equipment and infrastructure are exposed to corrosive chemicals and extreme temperatures. Polyurea coatings can withstand exposure to a wide range of acids, alkalis, and solvents without deterioration. Their thermal stability ensures that they remain effective in environments ranging from sub-zero to approximately 350°F (177°C), maintaining their protective properties without melting or breaking down.

Compared to epoxy coatings, polyurea exhibits superior chemical resistance and flexibility characteristics. Epoxy coatings are known for their hardness and durability, but over time they can become brittle and prone to cracking under stress. This brittleness can lead to microcracks that can allow moisture and chemicals to penetrate and cause degradation of the underlying substrate. On the contrary, polyurea retains its elasticity and integrity longer, even under mechanical loads and temperature fluctuations. This elasticity allows the coating to absorb impacts and accommodate substrate movements without cracking, thus maintaining an unbreakable barrier against environmental hazards.

The performance of Polyurea in environments with temperature fluctuations deserves special attention. Many materials expand and contract when the temperature changes, which leads to the formation of cracks and loss of protective properties. The ability of polyurea to stretch and return to its original shape without damage allows it to effectively cope with thermal cycling. This property is particularly useful in applications such as pipelines and storage tanks where thermal expansion and contraction are frequent.

The abrasion resistance of polyurea coatings is another factor contributing to their durability in harsh environments. Industrial floors, heavy equipment and vehicles are constantly exposed to friction and impact, which can wear down the coating. Polyurea’s high tensile strength and abrasion resistance, often exceeding 20 mg loss per 1000 cycles in the Taber abrasion test, ensure that the coating remains intact and continues to protect the substrate over time.

Polyurea coatings exhibit excellent water resistance, preventing the ingress of moisture that can lead to rust and other forms of water damage. In environments where surfaces are constantly exposed to water or high humidity, such as sewage treatment plants and underground structures, polyurea acts as an effective moisture barrier. Its hydrophobic nature ensures that water does not seep through the base, thereby preventing corrosion and extending the life of the infrastructure.

Advanced polyurea formulations may also contain additives to improve specific properties such as fire resistance, UV resistance, and antimicrobial properties. Fire-resistant polyurea coatings can inhibit the spread of fire and smoke in the event of a fire, offering additional protection in fire-hazardous environments. UV stabilizers can be added to increase the resistance of the coating to UV radiation, making it suitable for outdoor use in constant sunlight.

Application in Construction

In the construction industry, the life of protective and decorative coatings is a critical factor in determining maintenance schedules and overall costs. Polyurea is increasingly used for waterproofing basements, garages, and roofs due to its quick hardening and long-term use. Its ability to adhere to a wide range of substrates, including concrete, metal, and wood, further enhances its versatility.

When comparing polyurea with traditional materials such as polyurethane, we see clear advantages. Polyurethane, which is often used for similar applications, usually has a shorter lifespan because it is less resistant to UV degradation and chemical attacks. In addition, polyurethane coatings usually take longer to harden, which can delay construction.

In terms of lifespan, polyurea coatings can last for several decades with minimal maintenance. This is a significant improvement over polyurethane and even epoxy coatings, which may require more frequent reapplication and touch-ups. Over the life cycle of a construction project, reducing the need for maintenance and replacement not only saves money but also minimizes failures.

Economic Considerations

The initial cost of polyurea coatings can be higher than some alternatives, raising questions about their cost-effectiveness. However, when evaluating the total cost of ownership, polyurea is often the more economical choice. This is due to its high durability, lower maintenance requirements, and longer service life. Businesses and organizations that invest in polyurea coatings can expect fewer repairs and replacements, resulting in significant long-term savings.

In industrial applications where downtime results in lost profits, polyurea’s quick cure time is another economic advantage. Facilities can resume operation much more quickly than with coatings that require a longer drying period. In addition, polyurea’s ability to withstand a variety of destructive factors means it provides continuous protection over time, reducing the risk of costly damage and downtime for repairs.

From a sustainability perspective, the durability of polyurea coatings means less frequent use of materials and resources for maintenance and replacement, which is beneficial for both the environment and the economy. Durable pavements contribute to the achievement of sustainable development goals by extending the life of infrastructure and reducing waste.