Polyurea coatings have revolutionized industrial surface treatments with their superior protective qualities. These elastomeric compounds boast unparalleled durability, chemical resistance, and a rapid curing time, making them the choice solution for safeguarding a variety of surfaces in harsh industrial environments. The applications of polyurea coatings span across sectors, safeguarding infrastructure, machinery, and equipment against wear, corrosion, and other forms of deterioration.

Polyurea coatings have revolutionized industrial surface treatments with their superior protective qualities. These elastomeric compounds boast unparalleled durability, chemical resistance, and a rapid curing time, making them the choice solution for safeguarding a variety of surfaces in harsh industrial environments. The applications of polyurea coatings span across sectors, safeguarding infrastructure, machinery, and equipment against wear, corrosion, and other forms of deterioration.

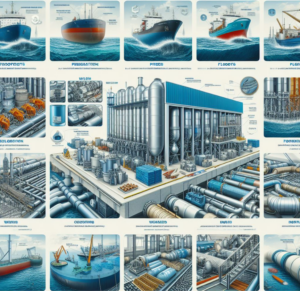

Versatility is at the heart of polyurea coatings, with their wide-ranging application in industrial protection attributed to their superior physical attributes. This material exists as a two-component system that, when mixed, becomes a rubber-like membrane with excellent adhesive qualities. Its ability to bond to numerous types of surfaces makes it a go-to solution for enduring protection across sectors including, but not limited to, automotive, marine, and construction.

Polyurea’s resistance to impacts and abrasion is particularly valuable. It is frequently applied for underbody coatings and truck bed liners, providing a robust barrier against the daily assault of road debris, salts, and extreme temperatures. Incorporating these protective coatings is a strategic choice for vehicle longevity, ensuring that cars, trucks, and other automotive equipment remain in optimal condition for longer periods.

The marine industry taps into the protective strengths of polyurea as well. Subjection to harsh sea conditions demands a safeguard against persistent moisture and salt, both of which can severely compromise the integrity of vessels and structures. Polyurea coatings are skillfully utilized to shield boats, docks, and even the expansive platforms operating offshore, offering a defense against the relentless threat of corrosion and material decay.

Polyurea coatings find a significant role in the construction industry. Their application spans a broad spectrum, from sealing roofs against the elements to providing a durable lining for concrete foundations. The use of these coatings is a proactive measure to prevent the insidious creep of moisture that can weaken structures and lead to expensive repair work. By incorporating polyurea, the construction sector enhances the durability of buildings and infrastructure, safeguarding against inclement weather and the wear and tear that buildings are subjected to over time.

Beyond these sectors, the adaptability of polyurea coatings can be seen in numerous other applications where protection from the elements, chemicals, or mechanical wear is a priority. This includes their use in flooring systems within industrial facilities, where resistance to chemicals and heavy traffic is paramount. They are also employed in the lining of water tanks and pipes, where their waterproof properties help to prevent leaks and preserve the quality of the stored contents.

Polyurea has emerged as a preferred material for protective coatings, providing industries with a reliable means of guarding their assets against a variety of potential damages. Its customizable nature allows it to fulfill specific protective requirements, while its rapid curing time aids in minimizing downtime during maintenance procedures. It is these characteristics that enable polyurea to meet the needs of industry professionals seeking to maintain operational integrity and prolong asset lifespan.

Enhancing Seamless and Aesthetic Finishes

Industrial finishing plays a crucial role in both the protection and the visual enhancement of commercial and industrial environments. Polyurea coatings have emerged as a leading solution in this space, offering a combination of durability and aesthetic appeal that is difficult to match with other materials.

An advantage of polyurea coatings is their versatility. They can be tailored to an array of textures and an extensive palette of colors, catering to specific design requirements. This allows facilities to maintain a cohesive and branded look across their floors, walls, and infrastructure. The seamless nature of polyurea coatings not only contributes to a sleek and modern appearance but also facilitates a more hygienic environment by eliminating seams and joints where dirt and pathogens might accumulate. This is particularly beneficial in sectors where cleanliness is paramount, such as food processing, healthcare, and pharmaceuticals.

Maintenance and longevity are two critical factors considered when selecting floor and wall coatings in commercial and industrial settings. Floors that endure high foot traffic, frequent spills, or the stress from heavy machinery must have a coating that can withstand such demands. Polyurea coatings are known for their strong resistance to abrasions, chemicals, and impacts, making them an excellent choice for preserving the integrity of the substrate over time. Their resilience translates into reduced maintenance costs and less frequent need for repairs or replacements.

The speed of application is another significant benefit polyurea coatings provide. They are renowned for their rapid cure times, which is particularly advantageous in industries where downtime equates to lost revenue. Manufacturers, for instance, can apply the coating and have their facilities back in service in a fraction of the time it takes other coatings to dry and cure. This efficiency supports uninterrupted production flows and ensures that safety and aesthetics are swiftly restored without impacting the bottom line.

For architects and engineers, the adaptability of polyurea coatings means that they can design visually appealing spaces. These coatings can be integrated into a wide range of architectural styles and industrial applications, proving their worth as a comprehensive solution for both new constructions and refurbishments.

Finally, environmental and safety considerations are increasingly at the forefront of industrial operations. Polyurea coatings contribute to safer work environments by providing slip-resistant surfaces as an option. Additionally, certain formulations of polyurea are developed with low volatile organic compound (VOC) emissions, supporting efforts to create greener facilities and reduce harm to the environment.

The use of polyurea coatings offers a blend of utility and aesthetics, with advantages encompassing seamless finishes, ease of cleaning, rapid cure times, and the capacity for various customizations. These traits make polyurea a commendable choice for a wide array of industrial and commercial applications, where both appearance and performance are essential to success.

Longevity and Cost-Effectiveness

Longevity and cost-effectiveness are crucial factors to consider in industrial applications when it comes to protective coatings. The durability of a coating can greatly impact its overall value, with longer-lasting solutions providing more financial benefits over time.

Polyurea coatings stand out in the industrial sector due to their exceptional durability. These coatings can endure extreme temperatures, resist damage from harsh chemicals, and absorb mechanical impacts that would typically cause substantial wear and tear on less robust coatings. The resilience of polyurea significantly reduces the need for frequent repairs or replacements, which is a key financial consideration for any industrial operation.

In manufacturing environments, especially those that handle harsh chemicals, the value of polyurea coatings is evident. They serve as an effective barrier on floors and containment systems, protecting these surfaces from spills or leaks that can lead to extensive damage and expensive downtime for cleanup and repair.

Applying polyurea to assets such as bridges and pipelines, which are constantly exposed to outdoor elements, provides a formidable line of defense against UV degradation, temperature swings, and environmental pollutants. By bolstering the asset’s resistance to these factors, polyurea coatings effectively extend the useful life of infrastructure, thus reducing the need for periodic and costly maintenance.

The financial implications of choosing polyurea are substantial. The reduced frequency of application, combined with the lesser extent of maintenance required, positions polyurea as a financially prudent option throughout the life cycle of an array of industrial applications.

Factoring in the quick drying and curing times, these coatings minimize operational disruptions, allowing for a more efficient workflow and safety for personnel. Additionally, the versatility in appearance gives industries the advantage of customizing the look of their assets without sacrificing protection.

With the diverse industrial applications that can benefit from the implementation of polyurea coatings, they stand as a premier choice for maintaining and extending the functionality and appearance of industrial assets. As commercial sectors advance and new operational demands arise, the adaptability of polyurea coatings to a wide range of conditions and their strong protective qualities underscore their ongoing value. The integration of these coatings into industrial maintenance strategies provides a financially astute approach to preserving and enhancing the longevity of valuable industrial assets and infrastructure.